Prices incl. VAT plus shipping costs

Free shipping from 600 EuroDelivery time: 2 - 4 working days

Order within 16 hours, 46 minutes and 11 seconds for guaranteed shipment tomorrow, 23.04.2025

- Order number: A0003894

- Producer EAN: 4018448109250

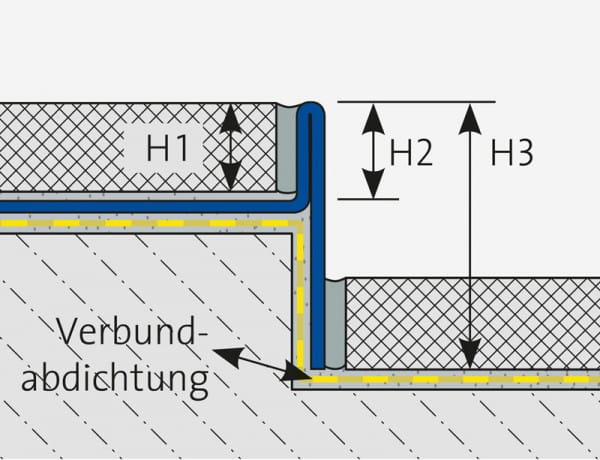

| Height 1: | 10 mm |

| Height 2: | 11 mm |

| Height 3: | 40 mm |

| Gradient: | 2 % |

| Material: | Stainless steel (V2A 1.4301) |

| Interface: | fine ground, brushed |

| Strength: | 1 mm ± 0,10 mm |

| Brand: | DURAL |

| Series: | SHOWER GK |

| Variant: | Left side |

- Height 1 = Maximum pavement thickness

- Height 2 = Total front height

- Height 3 = Total rear height

- Side selection facing the channel

Our DURAL inclined wedge made of finely ground stainless steel is perfect for installing your floor-level shower. The one-piece profiles form a 2% slope to ensure proper drainage. The slope wedges also clad the side cheeks of floor-level showers with the brushed surface, we offer extra variants here for the left and right side respectively. The one-piece inclined wedge is made of stainless stainless steel (V2A) and enables a visually appealing transition to the floor covering. The finely ground surface creates a uniform as well as high-quality look and is also easy to clean. The leg is also designed to allow flexible adjustment to deviations as well.

You can find further gradient wedges from DURAL made of high-quality V2A stainless steel in the lengths 98 cm, 120 cm, 148 and 200 cm as well as in the common heights (10 mm, 11 mm, and 12.5 mm) in our store.

Our tip from alleszumfliesen.de: Order your profiles 1-2 mm higher than the flooring you want to lay.

As a compound sealant, we recommend our ETAG-tested DURABASE ET-S Composite Waterproofing Systemhere you will find all the components you need!

Processing:

To shorten the profile, always cut the inclined wedge at the highest point.

Press the inclined wedge with perforated fixing leg into the fresh adhesive bed and align. Align the adjoining tiles so that the upper edge of the slope profile is flush with the tile. Cavity-free tile installation in the profile area - connecting joint 1.5 mm wide. Completely fill the joint space with grout.

Cleaning instructions

stainless steel never clean with abrasive media such as steel wool, as this may damage the surface, resulting in flash rust. Cleaning agents used must be free of chlorine and hydrochloric acid.